filament spunbond and needlepunched nonwoven geotextiles

Product Description

Filament geotextiles: Filament geotextiles are polyester filament needle-punched non-woven geotextiles, which do not contain chemical additives and are not heat-treated. They are environmentally friendly building materials. It can replace traditional engineering materials and construction methods, make construction safer, help environmental protection, and solve basic problems in engineering construction more economically, effectively and lastingly.

Filament geotextile has good mechanical function, good water permeability, anti-corrosion, anti-aging, and has the functions of isolation, anti-filtration, drainage, protection, stabilization, reinforcement, etc. Damage, creep is small, and the original function can still be maintained under long-term load.

Filament geotextile characteristics:

Strength - Under the same gram weight specification, the tensile strength in all directions is higher than other needle punched non-woven fabrics.

Anti-ultraviolet light - has a very high anti-ultraviolet ability.

Extremely high temperature resistance - high temperature resistance up to 230 ℃, the structure remains intact and the original physical properties are still maintained under high temperature.

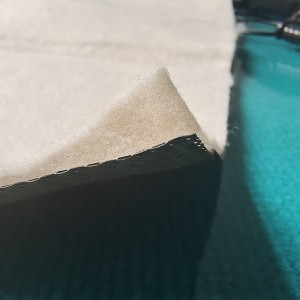

Permeability and Plane Drainage - The geotextile is thick and needle punched and has good plane drainage and vertical water permeability, which can be maintained for many years.

Creep resistance - The creep resistance of geotextiles is better than other geotextiles, so the long-term effect is good. It is resistant to the erosion of common chemicals in soil and corrosion of gasoline, diesel, etc.

Extensibility - geotextiles have good elongation under certain stress, making them adaptable to uneven and irregular base surfaces.

Technical characteristics of filament geotextiles: The thicker geotextiles can ensure the three-dimensional porosity of the geotextiles, which is conducive to the realization of excellent hydraulic properties.

The burst strength of geotextile has great advantages, especially suitable for retaining wall and embankment reinforcement. The indexes of geotextiles all exceed the national standards and are excellent geotechnical reinforcement materials.

This is a geotextile with three-dimensional pores produced from PET or PP by melt spinning, air-laid, and needle-punched consolidation processes.

Product Introduction

Product Specification

The gram weight is 100g/㎡~800g/㎡; the width is 4~6.4 meters, and the length is according to customer needs.

Product Features

High mechanical index, good creep performance; strong corrosion resistance, aging resistance, excellent heat resistance, and fine hydraulic performance.

Application Scenarios

Mainly used for reinforcement, filtration, isolation and drainage of water conservancy, hydropower, environmental protection, highways, railways, dams, coastal beaches, metallurgical mines and other projects.

Product Description

|

Item |

Indicator |

||||||||||

|

1 |

Mass per unit area (g/m2) |

100 |

150 |

200 |

300 |

400 |

500 |

600 |

800 |

1000 |

|

|

2 |

Breaking strength,KN/m≥ |

4.5 |

7.5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

|

|

3 |

Vertical and horizontal breaking strength,KN/m≥ |

45 |

7.5 |

10.0 |

15.0 |

20.0 |

25.0 |

30.0 |

40.0 |

50.0 |

|

|

4 |

Breaking elongation,% |

40~80 |

|||||||||

|

5 |

CBR bursting strength,KN≥ |

0.8 |

1.6 |

1.9 |

2.9 |

3.9 |

5.3 |

6.4 |

7.9 |

8.5 |

|

|

6 |

Vertical and horizontal tear strength,KN/m |

0.14 |

0.21 |

0.28 |

0.42 |

0.56 |

0.70 |

0.82 |

1.10 |

1.25 |

|

|

7 |

Equivalent pore size O90 (O95) /mm |

0.05~0.20 |

|||||||||

|

8 |

Vertical permeability coefficient, cm/s |

K×(10-1~10-3)where K=1.0~9.9 |

|||||||||

|

9 |

Thickness,mm≥ |

0.8 |

1.2 |

1.6 |

2.2 |

2.8 |

3.4 |

4.2 |

5.5 |

6.8 |

|

|

10 |

Width deviation,% |

-0.5 |

|||||||||

|

11 |

The quality deviation per unit area, % |

-5 |

|||||||||