Good Quality Geotextiles - staple fibers needle punched geotextile – Taixi

Good Quality Geotextiles - staple fibers needle punched geotextile – Taixi Detail:

Product Description

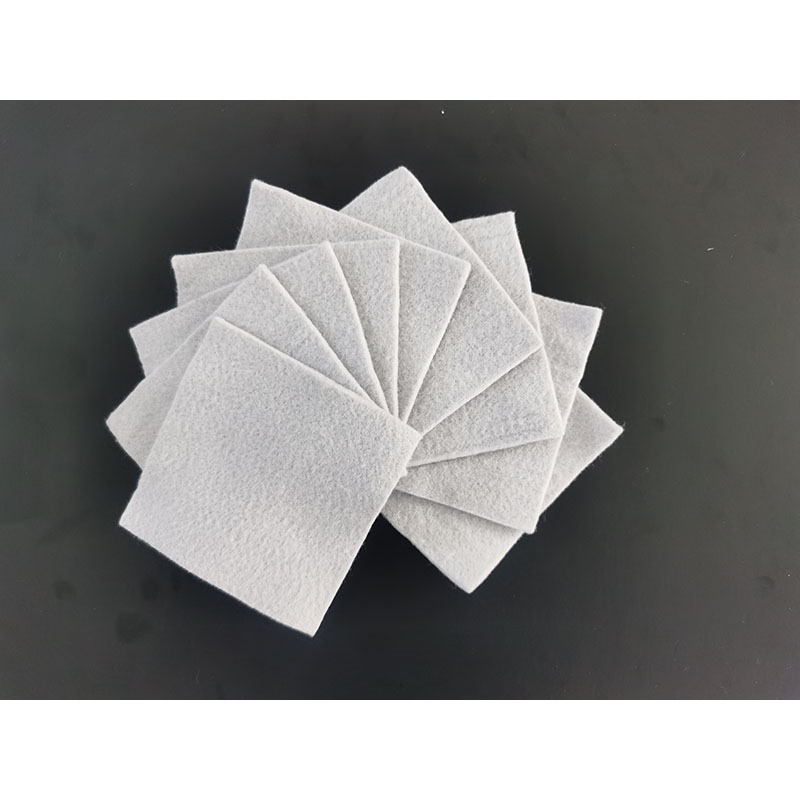

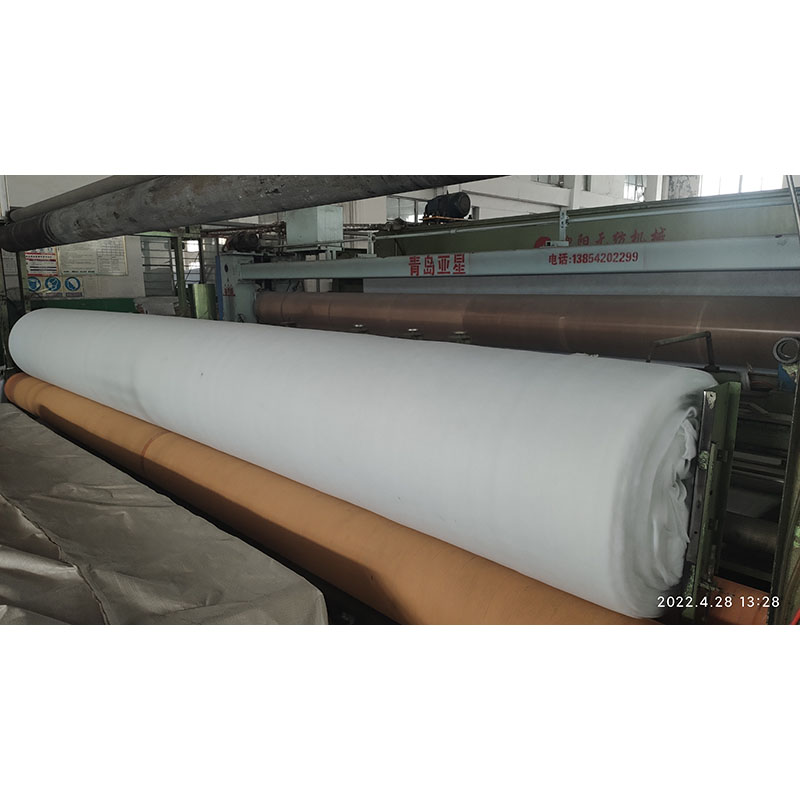

The short fiber geotextile has good water conductivity, and the short fiber needle-punched non-woven geotextile can create a safe channel for drainage pipes in the internal structure of the soil, and discharge excess liquid and waste gas in the soil structure; the use of geotextiles to improve the soil quality. Compressive strength and anti-deformation level, improve the stability of building structure, and improve soil quality; Efficiently diffuse, transmit or dissolve concentrated stress to avoid soil damage due to external forces; Avoid upper and lower layers of sand, gravel, soil It is doped between the body and cement; the mesh tissue formed by the amorphous connective tissue has strain and autonomous movement, so the pores are not easy to block; it has high water permeability and can still maintain good under the pressure of soil and water Water permeability; with polypropylene cloth or polyester and other chemical fibers as the main raw materials, it is corrosion-resistant, non-erosive, non-insect-resistant, and has anti-oxidation specifications and models: the width can reach 6 meters. It is the widest commodity in China, the utilization factor quality: 100-600g/㎡;

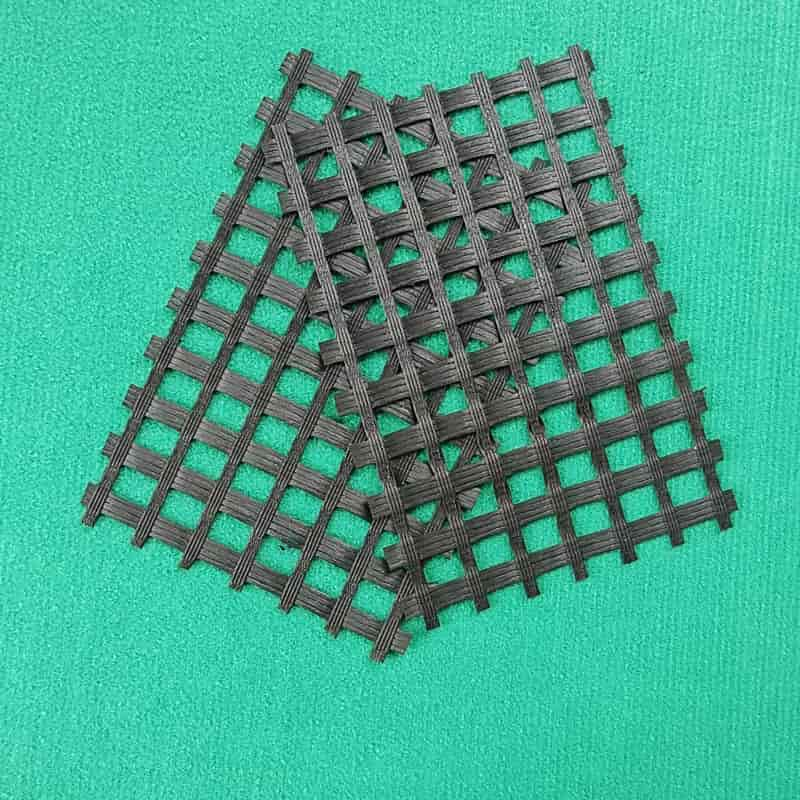

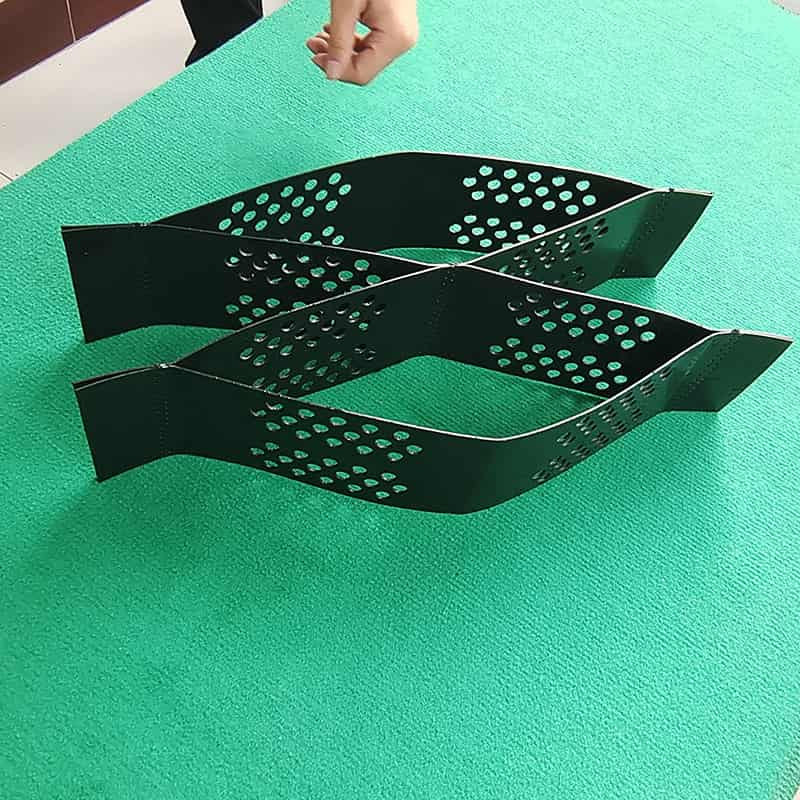

Staple fibers needle punched non-woven geotextile is made of PP or PET staple fibers and processed by on carding cross-laying equipment and needle punched equipment. It has the functions of isolation, filtration, drainage, reinforcement, protection and maintenance.

Product Introduction

Product Specification

The gram weight is 80g/㎡~1000g/㎡; the width is 4~6.4 meters, and the length is according to customer needs.

Product Features

It has good flexibility, corrosion resistance, acid and alkali resistance, as well as fine oxidation resistance; it has good water permeability, filtration and isolation performance, and it is convenient for construction.

Application Scenarios

It is widely used in water conservancy, hydropower, highways, railways, ports, airports, sports venues, tunnels, coastal mudflats, reclamation, environmental protection and other engineering fields.

Product Parameters

GB/T17638-2017 “Geosynthetics-Synthetic – Staple fibers Needle Punched Non-woven Geotextile”

|

Item |

Nominal breaking strength/(kN/m ) |

|||||||||

|

3 |

5 |

8 |

10 |

15 |

20 |

25 |

30 |

40 |

||

|

1 |

Vertical and horizontal breaking strength,KN/m≥ |

3.0 |

5.0 |

8.0 |

10.0 |

15.0 |

20.0 |

25.0 |

30.0 |

40.0 |

|

2 |

Breaking elongation,% |

20 ~100 |

||||||||

|

3 |

Bursting strength,KN≥ |

0.6 |

1.0 |

1.4 |

1.8 |

2.5 |

3.2 |

4.0 |

5.5 |

7.0 |

|

4 |

The quality deviation per unit area, % |

±5 |

||||||||

|

5 |

Width deviation,% |

-0.5 |

||||||||

|

6 |

Thickness deviation,% |

±10 |

||||||||

|

7 |

Equivalent pore size O90 (O95) /mm |

0.07~0.20 |

||||||||

|

8 |

Vertical Permeability Coefficient /(cm/s) |

KX(10-1 ~10-3) where K = l.0〜9.9 |

||||||||

|

9 |

Vertical and horizontal tear strength,KN ≥ |

0.10 |

0.15 |

0.20 |

0.25 |

0.40 |

0.50 |

0.65 |

0.80 |

1.00 |

|

10 |

Acid and alkali resistance (strength retention rate) % ≥ |

80 |

||||||||

|

11 |

Oxidation resistance (strength retention rate) % ≥ |

80 |

||||||||

|

12 |

UV resistance (strong retention rate) % ≥ |

80 |

||||||||

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We've got our personal factory and sourcing office. We can easily present you with almost every style of merchandise linked to our merchandise range for Good Quality Geotextiles - staple fibers needle punched geotextile – Taixi , The product will supply to all over the world, such as: Rwanda, Colombia, Miami, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!