OEM/ODM Manufacturer Biaxial Geogrid Bx1200 - Glass fibre geogrid – Taixi

OEM/ODM Manufacturer Biaxial Geogrid Bx1200 - Glass fibre geogrid – Taixi Detail:

Product Description

Fiberglass geogrid is the ideal geosynthetic material to reinforce the soft soil, cement, concrete, asphalt for the road surface or roadbed, etc. Fiberglass geogrid is made from excellent non-alkali fiberglass filament as the base material coated with adhesive by automatic woven technology. Fiberglass geogrid can can make full use of yarn textile strength and warp knitting directional structure to improve its high tensile strength, excellent tensile modulus, good wear resistance and creep resistance, and excellent thermal stability, etc. It can largely increase the bearing capacity of the ground and prolongs the service life of the road. Due to its high vertical and horizontal tensile strength, low unit extension and high flexibility, fiberglass geogrid is widely used to reinforce the embankment, asphalt pavement, road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.

It is a mesh structure material made of GE fiber as the main raw material, using advanced weaving process and special coating treatment process. It can improve the overall performance and is a new and excellent geotechnical substrate.

Product Specification

25-25, 30-30, 50-50, 80-80, 100-100, 120-120KN.

Product Features

Fiberglass Geogrid Features

High tensile strength and tensile modulus

Excellent wear resistance and creep resistance

Low elongation

Excellent temperature range

Good anti-age and alkali-resistance

Excellent thermal stability

Nesting, interlock and restraint effects

Overall improvement of road base

Especially suitable for all types of asphalt mixes

Extending service life

Easy installation

Fiberglass Geogrid Application

Reinforcement of roads and crack prevention for airport runways, taxiways, roads, bridges, parking lots, jointed concrete highways to control reflective cracking.

New highway construction, and other road maintenance or repair jobs to improve pavement life.

Expanding thoroughfares and road lanes.

Asphalt reinforcement at locations subject to intensive vehicle braking or accelerating, important junctions, bus stops etc.

It has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance and long work life. It can strengthen and reinforce the pavement; prevent rutting fatigue cracks, hot-cold expansion cracks and reflection cracks below; disperse the bearing stress of the pavement; and prolong the service life of the pavement.

Application Scenarios

1. Used for old asphalt concrete pavement; reinforced to strengthen the asphalt surface layer; prevent the road collapse;

2. The cement concrete pavement is converted into a composite pavement to suppress reflection cracks caused by plate shrinkage;

3. Road extension project to prevent cracks caused by the junction of new and old and uneven settlement;

4. Reinforcement treatment of soft soil foundation is conducive to the consolidation of soft soil water separation, effectively inhibits settlement, uniform stress distribution, and enhances the overall strength of the roadbed;

5. The semi-rigid base of the newly built road produces shrinkage cracks, and reinforcement is reinforced to prevent road cracks caused by the reflection of the base cracks.

Product Parameters

GBT21825-2008 “Glass fibre geogrid”

|

Item Specification |

EGA30-30 |

EGA50—50 |

EGA60-60 |

EGA80-80 |

EGA100-100 |

EGA120-120 |

EGA150-150 |

EGA200-200 |

|

|

Mesh Center Distance (mm) |

25.4×25.4或 12.7×12.7 |

||||||||

|

Break Strength (kN/m) |

Vertical |

30 |

50 |

60 |

80 |

100 |

120 |

150 |

200 |

|

Horizontal |

30 |

50 |

60 |

80 |

100 |

120 |

150 |

200 |

|

|

Break Elongation Rate w(%) |

Vertical |

4 |

|||||||

|

Horizontal |

4 |

||||||||

|

Temperature Endurance (℃) |

|

-100~280 |

|||||||

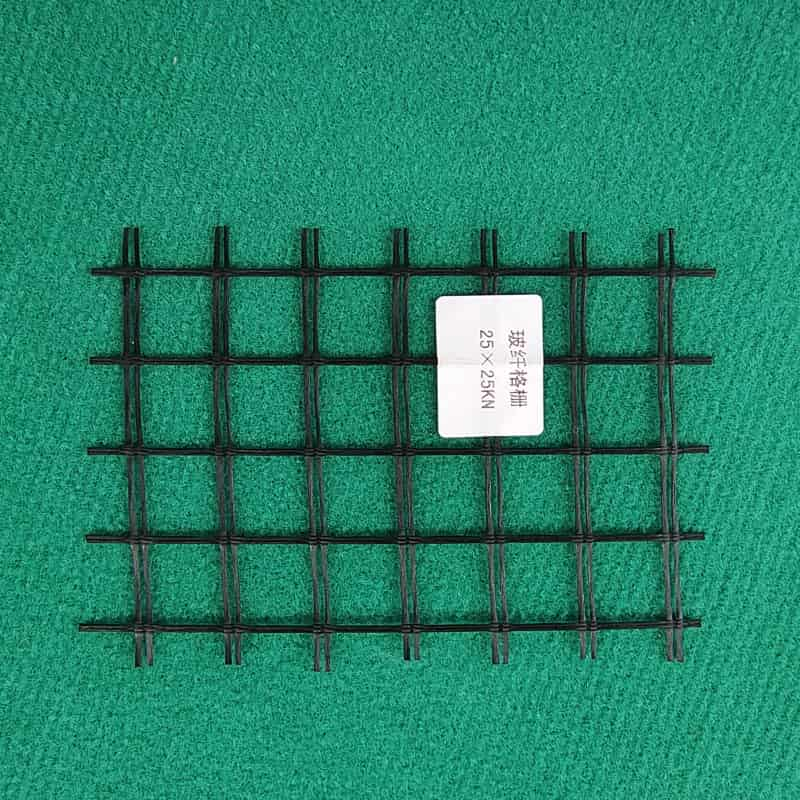

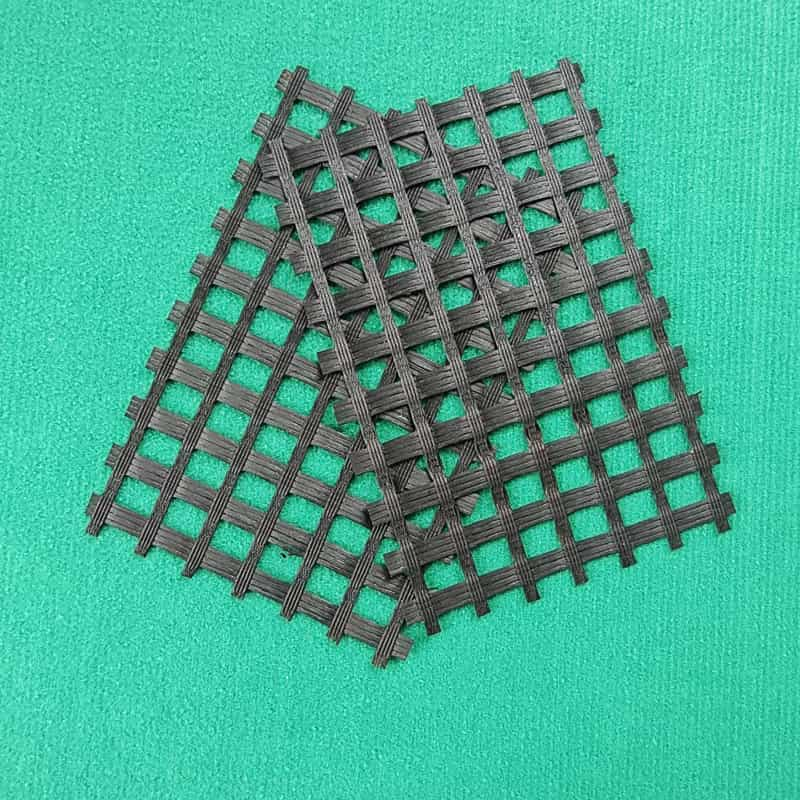

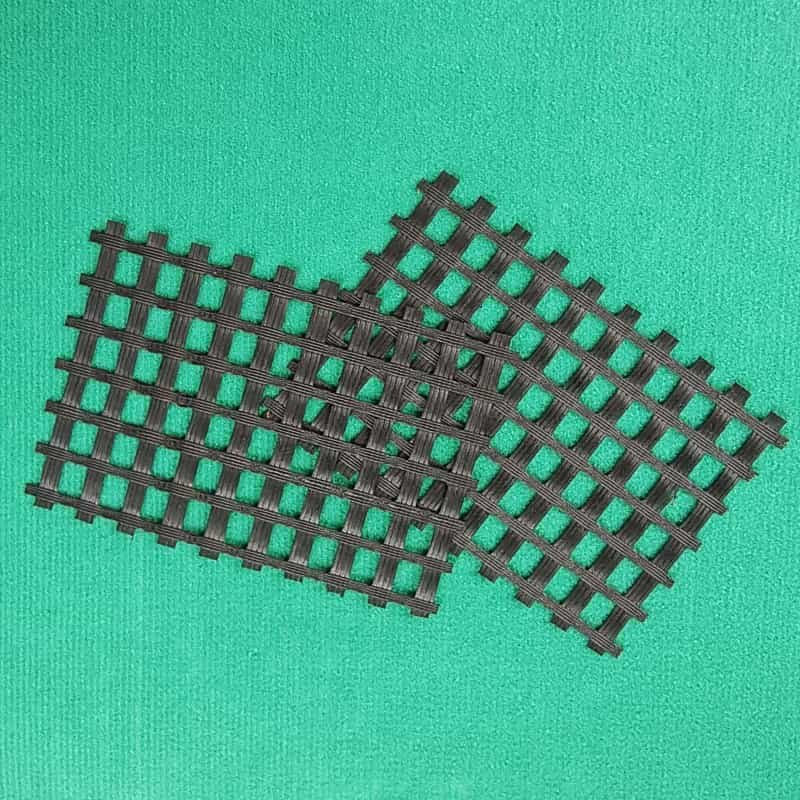

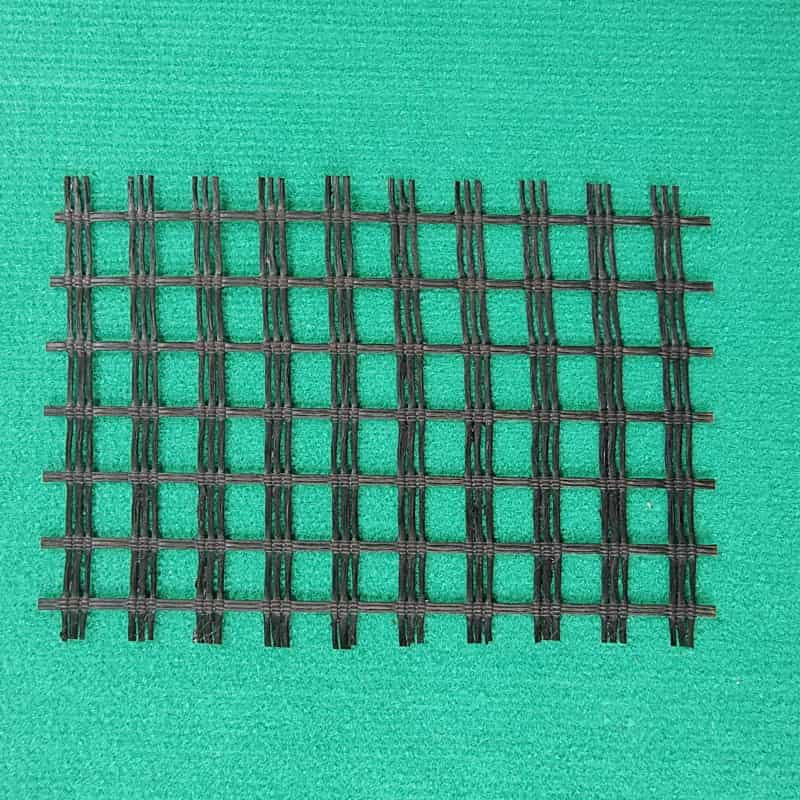

Product detail pictures:

Related Product Guide:

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for OEM/ODM Manufacturer Biaxial Geogrid Bx1200 - Glass fibre geogrid – Taixi , The product will supply to all over the world, such as: Argentina, Netherlands, Eindhoven, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.