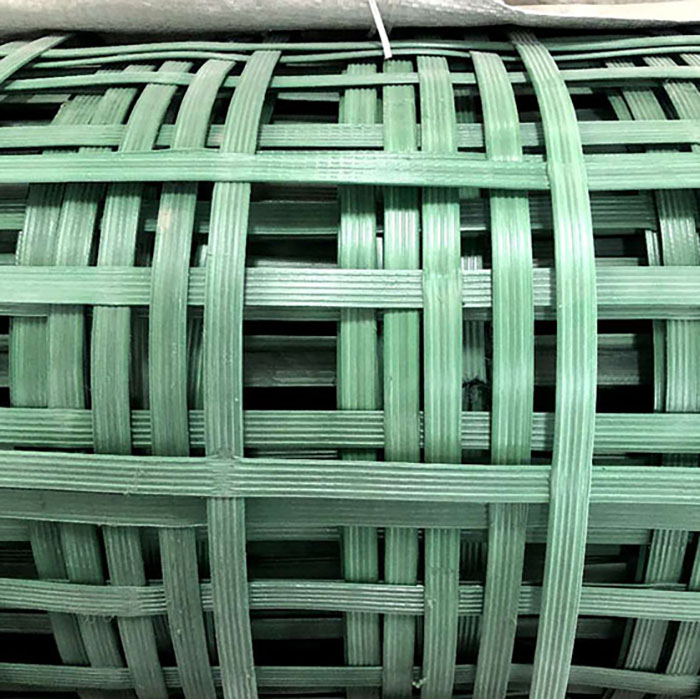

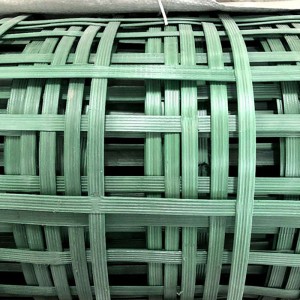

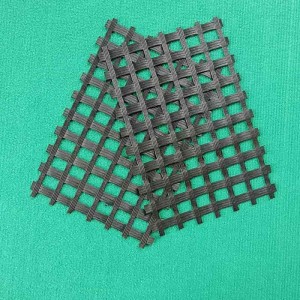

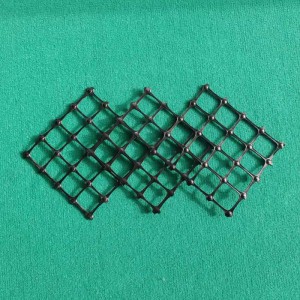

PP weld geogrid PP

Product Description

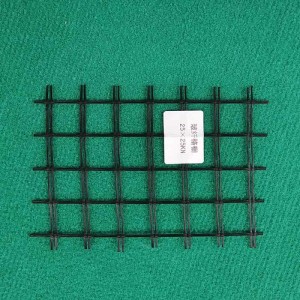

Product Specification:

Tensile Strength:25000-150000N/m;Elongation at Yield :12-13%;Grid Size:100~150mm;Width:4~6m.

Product Features:

1. PP weld geogrid has the properties of high strength, low elongation (breaking elongation not more than 12%), and its creep value is very small.

2. The grid is used to reinforce the foundation, improve the bearing capacity, reduce the uneven settlement, and resist the formation of the soil failure surface.

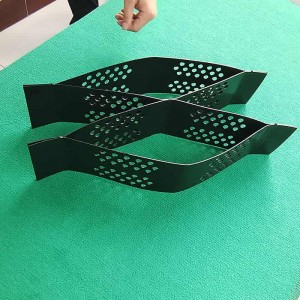

3. PP weld geogrid has good flexibility as the material is continuously stretched by strong tension and double-sided clamping of transverse rib belts, the performance of the geogrid is still maintained even if it is cracked.

4. The biaxial geogrid type uses polypropylene or other advanced materials and adds anti-ultraviolet additives. After extruding and stretching, it has great tensile strength in both vertical and horizontal directions, which is suitable for large-area, long-term bearing roadbed reinforcement.

Application Scenarios

It can be widely used in the reinforcement of weak foundations in the construction of highways, railways, bridge abutments, docks, slope protection, slag yards and other construction fields, as well as retaining walls and pavement crack resistance projects.

Product Parameters

See JT/T480-2002 “Geosynthetics in the traffic engineerings -Geogrid”

| limit tensile strength per metre length along the width direction KN/m | tension fracture strength per metre length along the width direction % |

limit tensile strength per metre length along the width direction after 100 freezing and thawing cycle KN/m |

tension fracture strength per metre length along the width direction

after 100 freezing and thawing cycle % |

Grid Space mm |

Freezing-Resistance ℃ |

Limit Peel Force at Sticky or Weld Point N |

|

|||||

|

Longitudinal |

Landscape |

Longitudinal |

Landscape |

Longitudinal |

Landscape |

Longitudinal |

Landscape |

Longitudinal |

Landscape |

|||

|

GSZ30-30 |

30 |

30 |

≤3 |

≤3 |

30 |

30 |

≤3 |

≤3 |

232 |

232 |

-35 |

≥100 |

|

GSZ40-40 |

40 |

40 |

≤3 |

≤3 |

40 |

40 |

≤3 |

≤3 |

149 |

149 |

-35 |

≥100 |

|

GSZ50-50(A) |

50 |

50 |

≤3 |

≤3 |

50 |

50 |

≤3 |

≤3 |

220 |

220 |

-35 |

≥100 |

|

GSZ50-50(B) |

50 |

50 |

≤3 |

≤3 |

50 |

50 |

≤3 |

≤3 |

125 |

125 |

-35 |

≥100 |

|

GSZ60-60(A) |

60 |

60 |

≤3 |

≤3 |

60 |

60 |

≤3 |

≤3 |

170 |

170 |

-35 |

≥100 |

|

GSZ60-60(B) |

60 |

60 |

≤3 |

≤3 |

60 |

60 |

≤3 |

≤3 |

107 |

107 |

-35 |

≥100 |

|

GSZ70-70 |

70 |

70 |

≤3 |

≤3 |

70 |

70 |

≤3 |

≤3 |

137 |

137 |

-35 |

≥100 |

|

GSZ80-80 |

80 |

80 |

≤3 |

≤3 |

80 |

80 |

≤3 |

≤3 |

113 |

113 |

-35 |

≥100 |

|

sSZ100-100 |

100 |

100 |

≤3 |

≤3 |

100 |

100 |

≤3 |

≤3 |

95 |

95 |

-35 |

≥100 |